Branch Feeder Monitor for Multi-circuit Power and Energy Metering

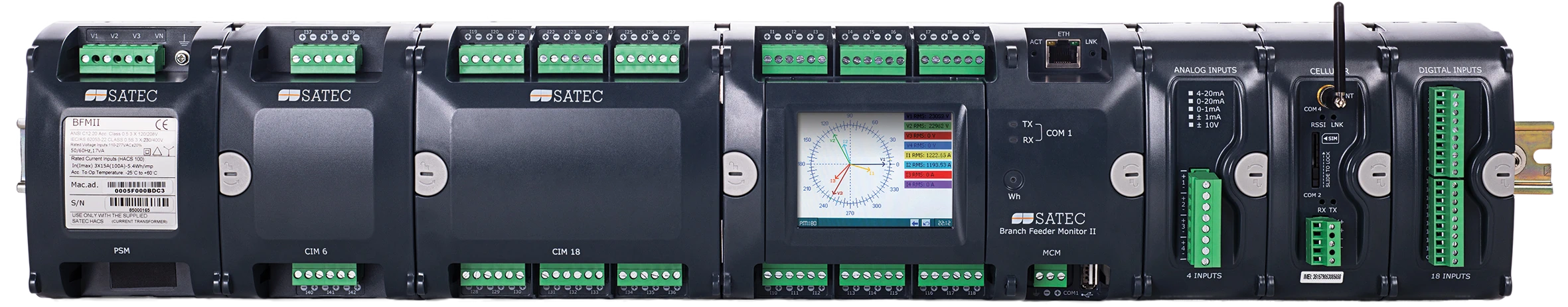

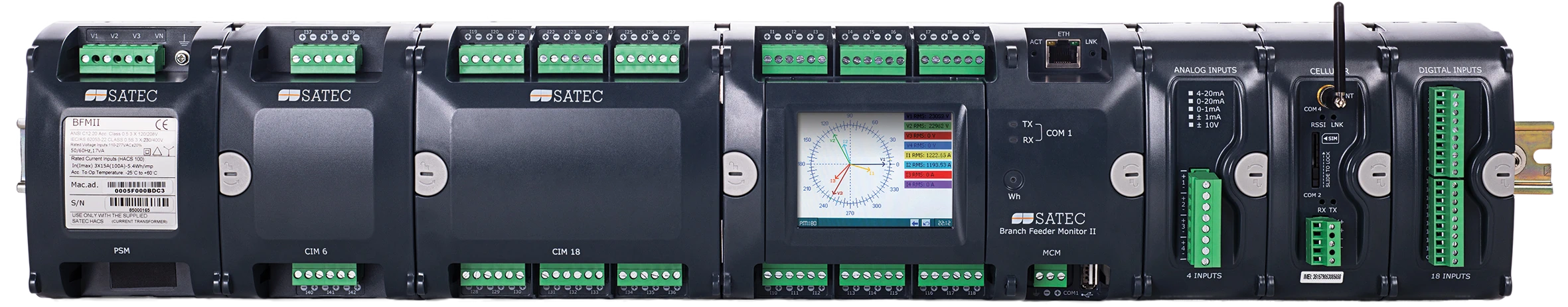

SATEC BFM-II

Fitting for both new and retrofit projects, SATEC Branch Feeder Monitor™ II, is a multi-circuit power meter, monitoring up to 18 three-phase power circuits or 54 single-phase, or any combination.

Cost-effective

- Significantly reduces installation costs and minimizes space requirements compared to using multiple legacy meters

Multi-circuit modular options for multi-load metering

- Up to 18 three-phase loads

- Up to 54 single-phase loads

- Various combinations of the two

Revenue Meter

- Class 0.5S accuracy per IEC 62053-22

- Tenant Billing & Monitoring

- Time-Of-Use (TOU) Metering

- Anti-tamper design

Communication

- Built-in ports: RS485; ETH

- Optional: 3G modem

- Protocols: Modbus, IEC 60870-5-101/104, DNP3.0, BACnet

Digital & Analog I/O (modular)

- Digital I/O: up to 72 digital I/O

- Analog: up to 16 inputs

Description

The Branch Feeder Monitor™ multi-circuit meter is ideal for both new and retrofit projects. It displays and logs parameter readings of energy, power and demand, along with multi-tariff (ToU) capabilities.

The BFM-II monitors up to 18 three-phase circuits, 54 single-phase circuits, or any combination of single, two-phase or three-phase circuits. This flexibility makes the BFM-II perfect for multi-tenant facilities such as residential projects, office buildings and shopping malls. Its modular design offers a selection of 18, 24, 30, 36, 42 or 54 channels to fit any requirement and to easily fit into existing panel boards or be flush mounted nearby, thus eliminating the need for expensive retrofit projects or for allocating extra space for the device.

The BFM II utilizes High Accuracy Current Sensors (HACS). These SATEC branded CTs act as a primary CT, with a product range of up to 3000A. These CTs feature low-burden milliamp outputs, feeding directly into the meter, making it a “One-CT” system, thus considerably increasing accuracy.

Equipped with an internal electronic switch, providing an automatic protection circuit, these CTs prevent fire hazards regularly associated with disconnected CT outputs, rendering shorting bars unnecessary. Due to the low output burden, it is possible to run wiring to loads up to 200m away, without any compromise to accuracy.

For billing purposes, single or multiple circuits can be defined for each customer. This flexibility allows simple reassignment of circuit groups without wiring changes, and easy changes when tenants move in and out.

It is designed for DIN-rail mounting, equipped with built-in communication ports and anti-tamper enclosures. Modular expansion allows installation of additional I/O modules and power supply.

Applications

Marketing Materials

Tenant Billing & Monitoring

Large and medium facilities, such as commercial buildings, residential complexes, shopping centers, malls, data centers and universities are facing an increasingly competitive environment in which tenants expect to receive better service for less cost. Tenant billing and monitoring is an ideal solution for guaranteeing, and increasing, a permanent revenue stream for facility owners, while providing improved service for tenants.

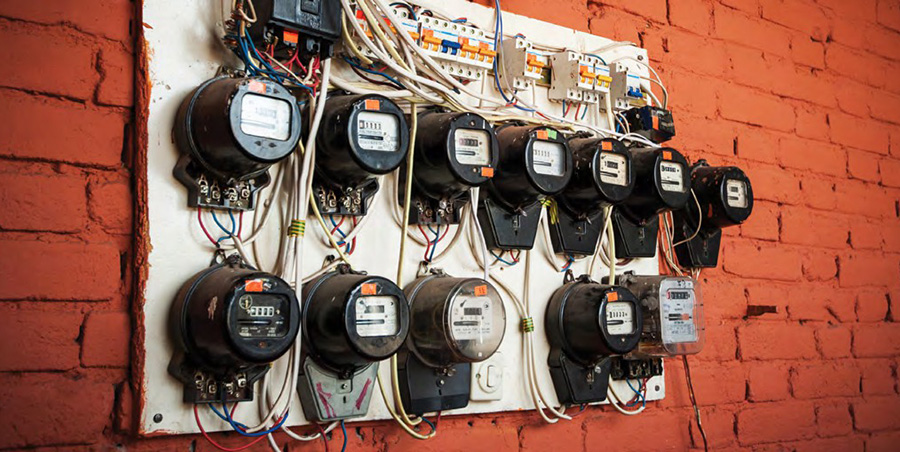

BFM-II vs 3-Phase Meters

In comparison with 3-phase meters, the BFM-II offers a great saving of cost, time and space, compared with typical installation:

- A single BFM-II device replaces up to 18 three-phase meters

- Saves 75% on installation cost, time, and panel space for 3-phase meters or 90% for single-phase meters.

- The BFM-II uses only 1 TCP/IP address for all submeters, compared with up to 54 addresses when using separate meters, thus making better use of IP Addresses.

Substation Enhancement

The BFM-II is designed to upgrade legacy substations featuring electro-mechanical (EM) relays, to provide realtime information and control over these highly reliable, yet limited, devices.

Many distribution substations utilize old EM protection relays with limited or no remote communication access. Normally, upgrading such substations is too costly and time consuming.

The revolutionary BFM-II makes the upgrade process simple and low-cost, providing very quick Return On Investment (ROI). Installation of the BFM-II upgrades the entire substation, without power-down, providing full load monitoring and control, using the optional digital and analog I/Os (Breaker Status).

One BFM-II monitors up to 18 three-phase circuits located up to 200m/650ft away from the device. The BFM II utilizes unique split-core High Accuracy Current Sensors (HACS) that simply clamp around the secondary wiring of the existing 5A secondary of the protection CTs. This eliminates the need to interfere with the protection circuit, eliminating the need for a full shutdown or interruption of the substation.

Utilizing our clip-on CTs cuts installation time by more than half of that needed for a traditional meter, thus an analog substation can be digitalized in just a few hours.

Installation no longer requires a “Trip Test”, thus saving on time and equipment. The BFM-II can be powered from either AC or DC, and programming and monitoring of each circuit is possible via the display, or the built-in USB port, using SATEC's free PAS Software. The information monitored is sent to the substation SCADA over serial communication or LAN.

Digital Fault Recorder

The BFM II is also available as a fault recorder version, capturing waveforms as high as 40 x In.

Providing fault recording on up to 36 current channels, this instrument truly revolutionizes distributed fault recording and substation digitalization, making it go literally from zero to sixty in half a day!

Advantages

- Ultra-rapid cost-effective substation upgrade without interruption of service

- Local and remote monitoring of relay & breaker operation, via digital inputs

- Digital Fault Recording with pre / post fault waveform capture on 36 current channels and 4 voltage channels

- Time-tagged fault events included in fault event report

- Triggered externally through device digital inputs, or internally from embedded fault detector

- Automatic detection of fault category using the sub-cycle measurements

- Fault triggers include programmable thresholds and hysteresis, adjustable for specific substation conditions

- Advance alert of possible trips trips, increasing network reliability

- Individual harmonics up to the 25th harmonic

- Substation communication protocols IEC 60870-5-101/104 and DNP 3.0

Data Centers

Energy consumption of data centers is constantly rising, following the increase in computing performance. Monitoring the PUE (Power Usage Effectiveness = total facility energy divided by the IT equipment energy) is is becoming prevalent and modern data centers now include rack level monitoring at the design stage.

The BFM-II monitors up to 54 single-phase loads and is ideal for PDU branch circuit monitoring, allowing for energy saving and offering high reliability. In addition to the above benefits, colocation centers can benefit substantially from tenant billing.

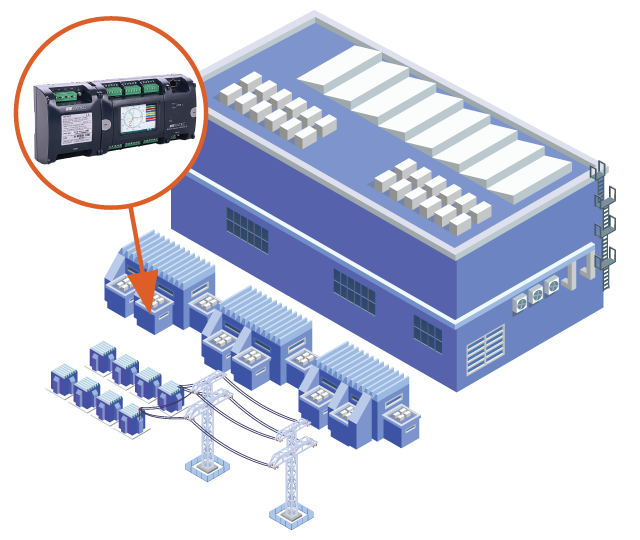

Industrial Plants

Typically, industrial plants have many loads that are fed from the same MCC. It has been proven that online monitoring of the consumption down to a single load level results in energy saving of up to 30%.

Utilizing the BFM-II is the most compact and efficient method for monitoring several loads located up to 200m from he device, with incomparable accuracy. The use of a single device rather than separate meters makes it easy to install and provides fully integrated communication, channeled through one single port, simplifying maintenance.

Plug-In Modules

The BFM-II supports various add-on modules:

- Current inputs

- Additional voltage inputs

- I/O

- Auxiliary power supply

- 2G/3G/4G modem

please see below for options and rules regarding possible combinations

Current Input Modules (CIM)

Up to 2 CIM modules per instrument

Up to 1 CIM module per instrument when employing VIM module (below)

- 6 current input module - HACS version

- 6 current input module - RS5 version

- 6 current input module - FLEX version

- 18 current input module - HACS version

- 18 current input module - RS5 version

- 18 current input module - FLEX version

2nd Voltage Input Set (VIM)

One Voltage Input Module (VIM) per device (optional) calibrated at either 50 Hz or 60 Hz.

Rating:

- Nominal voltage: 120/208 – 277/480V AC (L-N/L-L)

- Operating range: 70-561V AC 50/60 Hz

9 Relay Outputs

up to 2 RO modules per BFM

- 9 relays - SPST Form A

- Contact rating: 5A @ 250V AC, 5A @ 30V DC

- Update time: 1 cycle

9 or 18 Digital Inputs

up to 4 DI modules per BFM

- Optically isolated input, dry contact sensing (voltage-free)

- 24/125/250V DC

- Internal power supply 5V DC

- 1-cycle update time

- Unlatched, latched, pulse and KYZ operation

4 Analog Inputs

up to 4 AI modules per BFM

- Ranges (upon order):

- 0-1 mA (100% overload)

- ±1 mA (100% overload)

- 0-20 mA

- 4-20 mA

- Accuracy: 0.5% FS

- Scan time: 2 cycles

Cellular Communication

- Cellular Modem 2G/3G/4G

- Connector type: SMA

- Supported Protocols: MODBUS TCP (Port 502), DNP 3.0/TCP (Port 20000)

- Includes 2nd RS-422/485 communication port

Auxiliary Power Supply

- Withstanding Insulation: 4kV AC @ 1min

- AC/DC Power Supply: L/+, N/- and GND

- Rated input: 50-290V AC 50/60Hz, 40-290V DC (between -20°C to 60°C. In other temperatures from 90V DC), max. 10W

- Wire: 28-16 AWG (0.1-1.5 mm2), 600V isolation

- Terminal pitch 7.5mm, three pins

Tech Specs

-

-

Multifunctional 3-Phase Smart Meter

- Power: True RMS volts, amps, power, energy, power factor, neutral current, frequency, and many more

- Ampere/Volt demand meter

- 50/60 Hz measurements

- Event and parameter data-logging

- Sampling frequency: 64 samples per cycle

-

Harmonic Analyzer

- Individual voltage & current harmonic spectrum and harmonic angles up to 25th order harmonic

- Voltage and current THD, TDD and K-Factor

-

-

Revenue Meter / TOU Energy Meter

- Class 0.5S / 0.5 accuracy per IEC 62053-22 / ANSI C12.20 for active energy

- Anti-tamper design

- Bills up to 18 individual three-phase clients or 54 single-phase clients or various combinations in between

- Time-of-Use billing and logging: 8 energy/demand registers x 8 tariffs, 4 seasons x 4 types of days, 8 tariff changes per day, easy programmable tariff schedule

- Automatic 120-day daily profile for import/export energy and maximum demand readings (total and tariff registers) for each submeter

- Pulse reading via DI for water and gas meters

- Four-quadrant active and reactive energy poly-phase static meter

- Three-phase total and per phase energy measurements; active, reactive and apparent energy counters

- Automatic logging of daily energy and maximum demand profiles (total & TOU)

-

Waveform & Fault Recorder

Independent product; limited to 12 three-phase current channels.

- Digital Fault Recording with pre / post fault waveform capture on 36 current channels and 4 voltage channels

- Time-tagged fault events included in fault event report

- Triggered externally through device digital inputs or internally from embedded fault detector

- Automatic detection of fault category using the sub-cycle measurements.

- Fault triggers include programmable thresholds and hysteresis, adjustable for specific substation conditions

- Recording input waveforms and long-duration RMS trends during fault

-

-

Programmable Logical Controller

- Embedded programmable controller

- 4 control setpoints, programmable thresholds and delays for each submeter

- Relay output control (for alarm and protection)

- 1 cycle response and update time

-

Event and Data Recording

- Non-volatile memory for timestamped event and data recording for each channel

- Event recorder for logging internal diagnostic events and setup changes

- Two data recorders; 2 separate programmable data logs, on a periodic basis, per channel

-

-

-

Voltage & Power Supply

- Nominal voltage: 120/208 - 277/480V AC (L-N/L-L)

- Operating range: 70-561V AC 50/60 Hz (direct connection, L-L)

- Self-Energized from measured voltage

- Optional auxiliary power supply: 50-290V AC, 40-290V DC

-

Dual Voltage Inputs

- Voltage Input Module: a set of 3-phase voltage inputs for metering parallel power sources

- Calibrated at either 50 Hz or 60 Hz

- Every submeter can be assigned to one of the measured voltages

- Rating: identical to main voltage inputs (70 - 571V AC, L-L)

Note: When the VIM module is used, the total maximum amount of 3-phase current channels is 12

-

-

Variable Current Inputs

The BFM II features unique milliamp inputs. Each current-input module is ordered for individual compatibility with one of the three CT options below.

Modules may be mixed and matched within the 18- 54 circuit channels. Each module is specified to host only one of these 3 input options:

- HACS: 40mA HACS CT designated inputs (available HACS ratings: 100A-3000A)

- RS5: 40mA input designated for 5A split-core HACS for reading 5A from CT secondary, ideal for retrofit installation

- 3V AC: inputs for Flex Clamps (Rogowski Coil)

-

Digital and Analog I/O

Available I/O modules:

- 9DI: nine digital inputs

- dry contact / 24/125/250V DC

- 1-cycle update time

- unlatched, latched, pulse and KYZ operation

- energy pulses

- 18DI: eighteen digital inputs (max. 4 per device)

- 4AI: four analog inputs

- selection of 0-20mA, 4-20mA, 0-1mA and ±1mA output

- 2 cycle update time

- 9RO: nine form A relay outputs (max. 2 modules per device)

- 9DI: nine digital inputs

-

Communication Interfaces

- On-board interfaces:

- Standard 2-wire RS-485

- Ethernet (10/100Base-T)

- USB (Type A)

- Optional:

- 2G/3G/4G modem

- Client (Modbus/TCP over ETH or 4G)

- TCP notification client for communicating events or periodic reports to remote server

- Expertpower client on subscription basis

- On-board interfaces:

-

Communication Protocols

- Modbus RTU

- SATEC ASCII

- DNP 3.0

- IEC 60870-5-101 (optional)

- IEC 60870-5-104 (optional)

-

Meter Security

- 3 level password security for protecting meter setups and accumulated data from unauthorized changes

- Anti-tamper design (wiring seal)

-

Software Support

- Includes comprehensive Power Analysis Software (PAS) for configuration and data acquisition

- SATEC's Expertpower web-based energy management platform (subscription)

- Any 3rd party software supporting open-protocol

- Easily Upgradable Firmware through Serial or Ethernet ports

-

-

Display

- Optional 3.5” touch screen display with backlight

-

Mounting

- DIN-rail

-